Auswood Joinery enters new manufacturing era

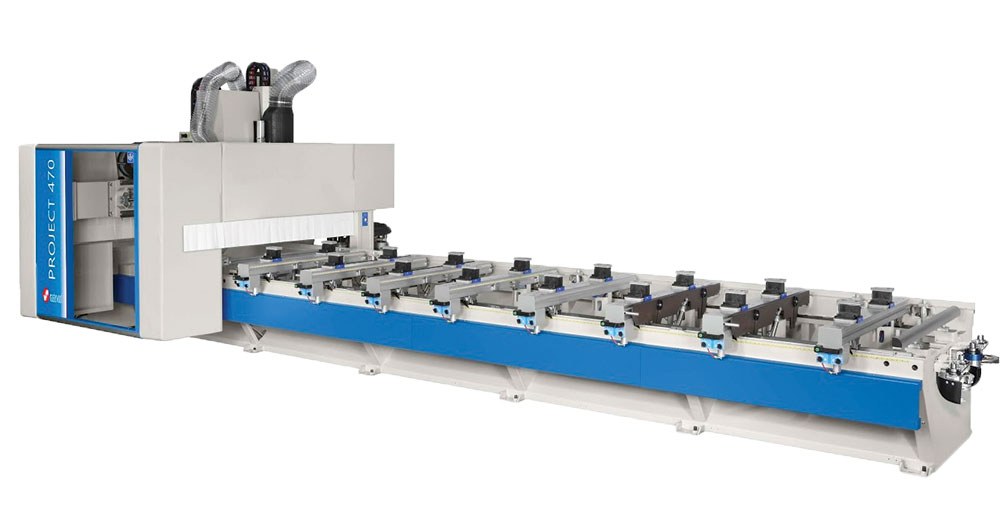

Auswood Joinery upgrades to Masterwood Project 470L CNC, boosting efficiency while preserving traditional craftsmanship values.

For nearly five decades, Auswood Joinery has been crafting bespoke staircases and ecclesiastical seating from its workshop in Magherafelt, Northern Ireland.

Established in 1977, this family-run business combines traditional joinery methods with cutting-edge technology to deliver precision-built, handcrafted products that stand the test of time.

When the company’s long-serving Masterwood Atlas CNC reached the end of its working life after more than twenty years of loyal service, the Auswood team knew exactly where to turn.

Time for a change

“We’d had the Atlas for over 20 years,” says Matthew Austin, Director at Auswood Joinery. “It served us brilliantly all that time, but we were due a change. It had been a real workhorse, but technology moves on, and we wanted to make sure we were keeping up.”

Having worked with Masterwood for decades, the decision to stay with the brand was an easy one. “We’ve always been happy with Masterwood,” Matthew continues. “The CNC has been reliable, and the customer service has always been spot on. We looked at a couple of other machines and compared prices – more out of curiosity than anything else – but Masterwood was always our go-to.”

Initially, Auswood considered upgrading to a five-axis model, but after discussions with the team at Masterwood GB, it became clear that a four-axis machine would more than meet their needs. “Kris advised that we probably wouldn’t need a 5-axis,” explains Matthew. “When we saw the Project 470L in action at their place, we knew that he was right. This was the machine for us.”

Set up for success

Installation was handled by Masterwood’s engineer, Mark, who ensured the process went without a hitch. “Mark ran the installation and he was great, it was all very smooth. He showed us how to use the machine and was more than happy to answer all our silly questions. It was top service that left us feeling confident with the new technology.”

Faster, smarter, and ready for the future

The new Project 470L has enhanced production for Auswood. “Quite a lot has changed in 20 years,” Matthew explains. “This machine is bigger, faster, and altogether more capable. We’re more efficient and crafting top-quality pieces with ease.”

The machine’s versatility has also opened up new opportunities. “With the changeable heads, we could easily branch out in future. The stairs are keeping us busy for now, but if we ever wanted to take on cupboard or other joinery work, we’d feel confident doing it with this CNC.”

Smarter stair design

Alongside the new machine, Auswood also upgraded its stair design software from the original MasterStair to StairBiz. “Upgrading to StairBiz has made life a lot easier,” says Matthew. “It’s really simple to programme, and there’s a lot more flexibility for bespoke projects. We just push a few buttons and it works the piece exactly the way you want it.”

A partnership built to last

For Auswood, the continued support from Masterwood GB remains a key part of the relationship. “Any time there’s a problem, we just give them a call and they sort it, no bother,” Matthew says. “In twenty years, the service has never faltered. Everyone’s friendly and they really know their stuff when it comes to CNCs.”

Looking ahead

With the Project 470L now firmly embedded in production, Auswood Joinery continues to uphold its long-standing ethos: keeping the tradition of craftsmanship alive while embracing the technology that ensures it thrives.

For more information or a demonstration of Masterwood’s machinery and software, contact Masterwood on 01293 402700 or email [email protected].