Helping deliver smarter Irish fit-out from factory floor to site

Elite Woodworking Machinery quietly cements its reputation as Ireland’s trusted, service-focused partner for joinery innovation.

Chris and Paula O’Connor

Elite Woodworking Machinery has quietly built a name as one of Ireland’s most trusted partners for joinery and interiors manufacturing – a family-founded business combining engineering rigour with practical manufacturing insight and a commitment to doing things properly. John Legg went to meet Managing Director Chris and Business Development Manager Paula O’Connor to learn how the company’s consultative approach is helping Irish manufacturers grow at home and abroad.

Elite Woodworking Machinery may not shout the loudest, but its footprint across Ireland’s woodworking, furniture and fit-out sectors has grown steadily over the past decade. From its base in Clonee, Dublin the company has developed from a small service-led operation into a trusted supplier and partner to joinery and interiors manufacturers of every scale. Today it offers a portfolio that spans compact entry-level machines through to fully automated CNC lines, sanding, edgebanding, extraction and spray-finishing systems – yet it is the way Elite engages with customers that defines it.

Foundations in hands-on experience

Elite’s story begins with two complementary backgrounds. Paula O’Connor grew up in a family manufacturing business – her father’s kitchen and bedroom company in County Meath. “I spent my teenage years cutting my teeth in kitchen assembly, edging, knocking up units,” she recalls. “That gave me a respect for the production floor and for the kind of pressures manufacturers face day-to-day.”

Chris, by contrast, came through an engineering route. “I was always more machinery-minded,” he explains. “When the recession came, I fell into the woodworking industry and began repairing and servicing machines. Before long, we had customers calling us out not just to fix their problems but to make sense of other suppliers’ equipment.”

Part of the Elite Woodworking Machinery team

From left: Chris O’Connor – MD, Brenda Casey – Head of Finance, Sean Duffy – Technician, and Paula O’Connor – Business Development Manager

That mixture of manufacturing and machinery experience soon pointed to a gap. “We were constantly being asked to repair issues caused by poor specification or indifferent support,” Chris says. “We thought – why are we fixing other people’s messes when we could supply something better ourselves?”

The business began life in 2013 under a sole-trader structure, re-forming as Elite Woodworking Machinery Ltd in 2020. Incorporating in the year of the pandemic might have seemed risky, yet Elite emerged stronger. “We were classified as essential services because many of our clients were producing hospital and healthcare furniture,” Paula explains. “That period tested our resilience, but it also gave us time to invest – in the showroom, in technology, and in finding new opportunities such as automated spray systems, which were under-represented in Ireland.”

Quiet growth – and a clear philosophy

From the outset, Elite positioned itself as a solutions provider rather than a catalogue seller – though without ever saying it in those marketing terms. Its emphasis is on machinery that is fit for purpose, built to last and properly supported. Paula describes the philosophy simply: “We want our customers to have the right equipment – not the most expensive, not necessarily the biggest – but the one that will solve their particular bottleneck and make them money.”

That integrity sometimes means turning business away. “We had one customer looking at a machine worth well over a hundred thousand,” Chris recalls. “It would have been easy to take the order, but his production volume just wasn’t there to feed it. We advised him to invest in a smaller model with room to grow. He came back later for the upgrade – and that, to us, is success.”

In a marketplace where many suppliers treat machinery as a one-off transaction, Elite’s emphasis on life-cycle partnership has resonated. “One of the things we pride ourselves on most is the after-sales service,” says Paula. “Our customers know they can pick up the phone and get a prompt response – not a ticket number.”

Leading Turkish brand, Oemak, manufactures a robustly engineered range of CNC machines. Currently ready for your demo in the Elite showroom is this Core X CNC router which is ideal for cabinetry, furniture making, signage, and custom woodworking, – a high-performance, multi-material CNC with an automatic tool-changer, touchscreen control, and extensive software compatibility.

Service designed around the factory floor

Elite keeps its service operation largely in-house. Engineers are factory-trained at the manufacturers’ own sites, ensuring they remain current with model changes and control systems. Routine servicing and preventative maintenance run alongside a tiered breakdown-response system that typically sees engineers on site within 24 hours. For new installations, factory technicians often join the team to complete commissioning and training, sharing updates on technology developments in real time.

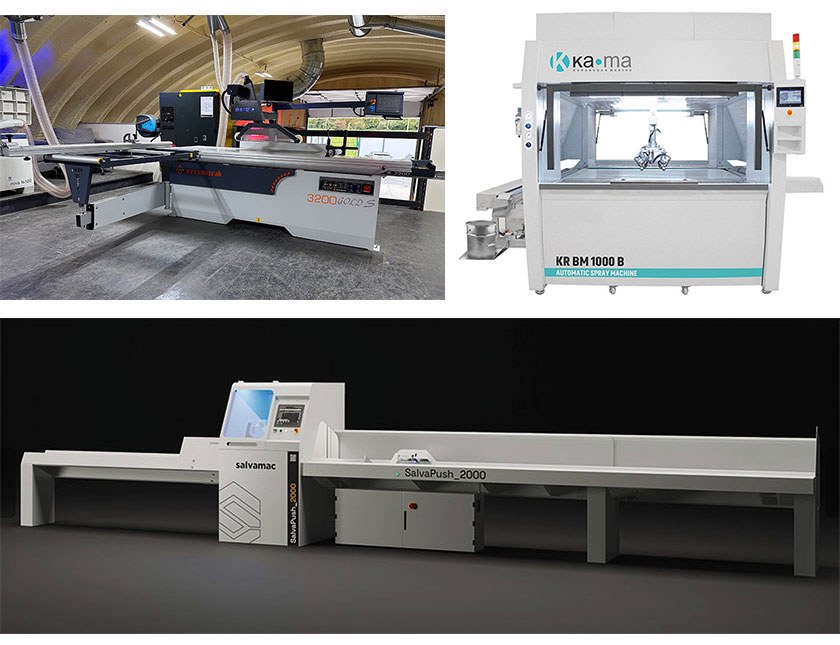

That approach has helped build strong relationships with manufacturers such as Kama, Oemak, Salvamac and a growing line of European finishing specialists. Chris and Paula personally visit each factory before taking on representation. “We look at how the machines are made, what materials and components are used,” Chris says. “We need to be sure of the build quality – because if a product isn’t reliable, we’re the ones getting the call when production stops.”

Meeting the needs of contract interiors

As Ireland’s interiors and fit-out market continues to expand, expectations on joinery and component manufacturers are tightening. Short lead-times, flawless repeatability and full traceability are now the rule. Elite’s range reflects this shift, bringing automation, energy efficiency and safety to every scale of workshop.

Automation addresses one of the industry’s persistent challenges – labour. “Across the board, clients tell us the same story,” says Paula. “They can’t get the people. The machines we’re bringing in help to bridge that gap. It’s not about taking jobs away – it’s about allowing manufacturers to keep up with demand when skilled labour isn’t available.”

Safety is another focus. Elite promotes systems that use cameras and AI to detect hands near cutting zones, automatically stopping exposed-blade machinery. The retrofit option, though costly, has found favour with education and training bodies where the protection of learners is paramount. “That technology is a game-changer for schools and colleges,” Paula notes. “It gives departments the confidence that students are working on equipment that mirrors current industry standards.”

The company’s involvement in the educational sector – from supplying industrial-grade machines to training support – is both commercial and cultural. “If students learn on the right equipment, they enter the workforce better prepared,” Chris says. “That benefits everyone.”

With the likes of Kama, Oemak, Salavamac, Ayza and other European brands, Elite Woodworking Machinery supplies a full range of quality equipment for those requiring CNC, joinery, saws, wood preparation, painting and finishing, extraction solutions

A bridge between Ireland and export markets

Although rooted in Ireland, Elite has always looked outward. Increasingly, the company supports Irish manufacturers that are exporting fitted-interior packages to the UK or mainland Europe. Its service capability extends across the border, and its specification advice reflects UK regulatory expectations and CE/UKCA compliance. “We can deliver, install and support in Northern Ireland and Britain just as easily as we do here,” says Paula. “That’s important for clients who are tendering internationally but want an Irish partner behind them.”

Corporate responsibility with local meaning

For Paula, community involvement is inseparable from running a business. Influenced by her parents – her father the entrepreneur, her mother a long-time foster carer – she has built social value into Elite’s operations. The company is a strategic partner of Way to Work, an organisation that creates employment pathways for young people leaving the care system. “We’ve taken apprentices through the programme, including one who is now a full-time technician on the road,” she says. “It’s a win-win – he has a secure career, and we gain a motivated employee.”

Elite also supports St Peter’s GAA Dunboyne through pitch-side sponsorship and youth initiatives. Paula herself has taken up sport in recent years. “It’s about community, connection and well-being,” she says. “You have conversations on the sideline that you might never otherwise have. That sense of belonging carries over into how we run the business.”

Looking ahead

As Irish contract interiors becomes ever more technically demanding – with shorter programmes, leaner budgets and greater emphasis on quality control – suppliers who can deliver reliability, service and insight will stand out. Elite Woodworking Machinery’s steady expansion is built not on scale or volume but on trust.

The company’s strategy for the coming years is measured but ambitious: to continue investing in showroom technology, expand its finishing and CNC offer, and strengthen its service network across the island. Export work will follow naturally, Paula believes, as Irish craftsmanship and manufacturing reputation grow.

“We’re not chasing size,” she says. “We’re chasing consistency – doing things properly, standing over what we sell, and building relationships that last. When a client buys a machine from us, they know we’re in it for the long term.”

For contractors, joinery specialists and manufacturers who depend on precision machinery to meet demanding programmes, that long-term commitment may prove the most valuable component of all.