New EU Formaldehyde regulation

What it means for the industry – and how MEDITE SMARTPLY has you covered

Santander Offices, Dublin. © Woodfit Acoustics

By David Murray

Head of Technical Affairs & Ireland Sales

MEDITE SMARTPLY

From 6th August 2026, a new EU revision under REACH (Annex XVII – Formaldehyde Restriction) will come into effect, halving the permissible formaldehyde release from wood-based panels. This landmark move, which is now widely regarded in the industry as “E05”, will see the limit ‘half’ from the current E1 classification (0.124 mg/m³) to the new E05 level (0.062 mg/m³).

First and foremost, it is important to emphasise that there are no health risks associated with the formaldehyde content of compliant E1 products. The revision comes as part of a review of the EU’s REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) Regulation, which is the central piece of European legislation governing the safe use of chemicals. In short, the EU is not banning formaldehyde, but is tightening the limits on how much can be emitted from composite wood products such as MDF, particleboard and plywood.

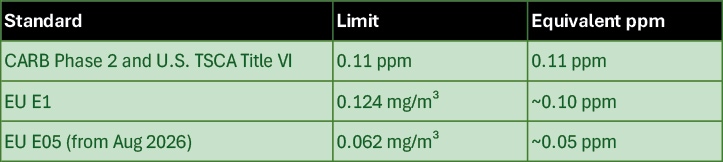

The new formaldehyde level effectively brings EU standards into line with the world’s most stringent regulations, such as the CARB Phase 2 and EPA TSCA Title VI standards in the United States. This ensures that European manufacturers and furniture exporters can compete easily in global markets, using one consistent set of ultra-low-emission materials. This is a positive development for Irish-manufactured MDF and for IWIN members given the excellent export-oriented work being done by Gareth Sherry and the IWIN network.

So to emphasise, the move from E1 to E05 under the revised EU REACH is a forward-looking, confidence-building measure. It’s about continuous improvement – not correcting a problem but ensuring the highest possible standards of sustainable construction, product quality, worker safety, and market trust. For the Irish joinery and interiors industry, it means working with suppliers who are ready – and MEDITE SMARTPLY is one of them.

King Fahad Cultural Opera Center, Saudi Arabia – Product used: MEDITE OPTIMA

© Woodfit Acoustics

Why is formaldehyde used in MDF?

Formaldehyde has long been used in MDF and similar wood-based panels as part of the resin binder system that holds wood fibres together. It delivers strength, durability, and cost-effectiveness, making MEDITE MDF one of the most versatile and machinable materials in joinery, cabinetry, and interior fitouts.

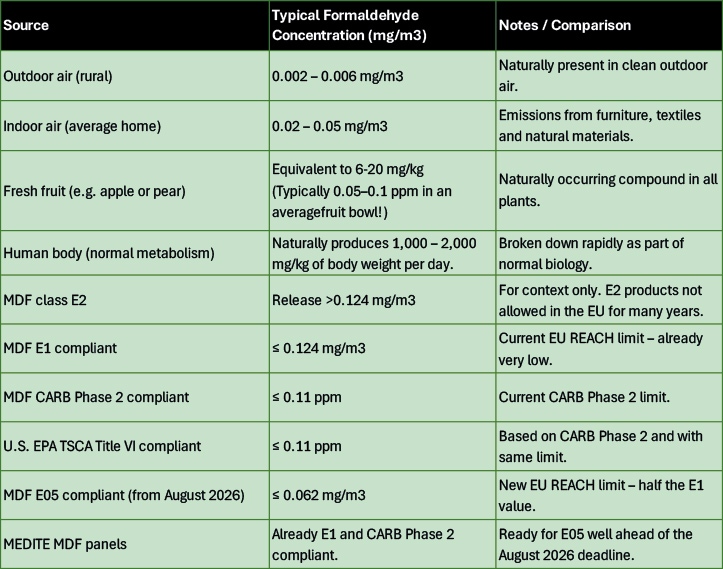

Importantly, the amount of formaldehyde used – even under the existing E1 limit – is extremely low and is not harmful to human health. In fact, formaldehyde is a naturally occurring compound found in all living things including plants, trees, and even in the human body. Everyday sources such as a bowl of fruit release more formaldehyde into the air (typically 0.05-0.1 ppm) than MEDITE MDF panels! (Disclaimer: we don’t recommend eating our MDF, but if you did … the human body would simply break down the tiny amount of formaldehyde as part of metabolic process which converts formaldehyde into carbon dioxide, which is then exhaled). Formaldehyde does not accumulate in the environment or within plants or animals. See Table in News section, comparing formaldehyde emissions in everyday life and MDF panels.

Setting the global benchmark

While Europe transitions to the new revision of REACH, market-leading MDF and OSB manufacturer MEDITE SMARTPLY – owned by Coillte, Ireland’s state forestry company – is already well ahead of the curve. Since 2010, MEDITE MDF products have not only met the European E1 standard but also the more stringent CARB Phase 2 (California Air Resources Board) limit as well as the U.S. EPA’s TSCA Title VI requirements.

To put this into context – for MDF – thee figures (shown below) demonstrate how the new European E05 limit is even more demanding than what is widely regarded as one of the world’s most stringent formaldehyde standards.

Debunking the “MDF ban” myth

Speaking of the USA, a persistent myth that is often cited in the trade claims that MDF is “banned” in the USA – this is entirely false. MDF remains fully legal to manufacture, distribute, and use across the United States. The confusion stems from the U.S. Formaldehyde Standards for Composite Wood Products Act, part of the Toxic Substances Control Act (TSCA) Title VI, which enforces stringent emission limits aligned with CARB standards. MEDITE has voluntarily complied with these limits since 2010 – long before they became law – ensuring that MEDITE MDF can be safely specified for green building projects worldwide.

Does the new E05 regulation apply to Northern Ireland?

Yes. Under the Windsor Framework (modification to the Northern Ireland Protocol, signed in February 2023), Northern Ireland continues to align with relevant EU product safety and environmental regulations, including REACH, meaning the new E05 formaldehyde restriction will apply there from August 2026. However, the EU REACH revision does not directly apply to Great Britain, which operates under a separate UK REACH regime.

Practically though, this presents many complex challenges for MEDITE’s long-standing customers in GB, because many MEDITE products exported to GB end up back in Ireland and other EU countries as part of finished components and systems. Furthermore, from a manufacturing and testing/certification perspective, producing and dual-stocking E1 and E05 products would add too much cost and complexity to an already multilayered supply-chain. For these reasons, MEDITE has taken the decision to begin the transition of its entire MDF production to the new E05 emission limit from January 2026, with completion by early April 2026.

Putting Formaldehyde into context for the Irish Contract Interiors Network. This table compares formaldehyde emissions in everyday life and MDF panels.

(For illustrative purposes only due to the complexities of correlating different units, and variations in the natural environment. Produced in collaboration with IWIN and MEDITE SMARTPLY).

Tested, certified and easy to comply

As you would expect from a market leader, Certification and clear documentation goes without saying.

Every MEDITE MDF product undergoes independent third-party testing to verify compliance with formaldehyde emission limits and other essential performance characteristics. Each product is CE and UKCA Marked and supported by a separate Declaration of Performance (DoP), clearly stating its formaldehyde emissions classification and technical performance, giving customers complete confidence and transparency.

By providing this documentation and Certification as standard, MEDITE SMARTPLY makes compliance effortless – saving contractors, joiners, and specifiers time and effort while ensuring full alignment with both current and forthcoming legislation. It’s part of the company’s commitment to not just meet the requirements, but also to make it easy for customers and end-users to comply.

National Opera House, Wexford – products used: MEDITE FR-B

©Woodfit Acoustics

Thought leadership through innovation and empathy

At MEDITE SMARTPLY, leadership means more than technical compliance – it means having our customers’ backs. That’s why all MEDITE MDF products will transition to E05 compliance by early April 2026 – a full four months before the EU regulation takes effect.

This gives distributors, fabricators, and fit-out specialists’ ample time to adjust seamlessly and makes the transition as easy and stress-free as possible, ensuring every customer remains fully compliant while maintaining the exceptional quality, performance and finish that MEDITE is best known for.

‘No added Formaldehyde’ (NAF) options

For specifiers and clients who wish to eliminate added formaldehyde altogether, MEDITE already offers four MDF products manufactured with ‘No Added Formaldehyde’ (NAF) resins. One example is MEDITE CLEAR, which is regularly used for fitting out sensitive environments such as schools, healthcare facilities, museums as well as certified green public buildings worldwide.

Royal Guard of Oman theatre, Oman

© Woodfit Acoustics

In parallel, MEDITE’s sister company, SMARTPLY, produces its entire OSB range using ‘No Added Formaldehyde’ polyurethane-based resin systems. This not only ensures extremely low emissions but also offers superior moisture resistance, making SMARTPLY OSB suitable for Service Class 2 (humid protected exterior) structural applications – whereas most standard MDF is suitable for Service Class 1 (dry interior) non-structural use. One notable exception to this Service Class rule is MEDITE TRICOYA EXTREME (MTX) which is guaranteed to last at least 50 years outside, and is also a NAF product.

Supporting green building standards

MEDITE’s commitment to ultra-low emissions supports a wide range of voluntary green building standards such as LEED, BREEAM and WELL, helping specifiers achieve high-performance, low-VOC interiors without compromising machinability, paint finish, or reliability in workshops across Ireland.

Protecting business, people, and the planet

The forthcoming E05 limit, whilst undoubtedly challenging from a manufacturing perspective, is a positive evolution for MDF – one that reflects Europe’s focus on healthy and sustainable building materials. MEDITE SMARTPLY’s proactive approach ensures that customers can move forward with confidence, knowing they’re supported by a manufacturer that combines technical excellence, environmental responsibility, and genuine empathy for the pressures of the trade.

From the forest floor to the fit-out floor, MEDITE SMARTPLY continues to set the benchmark – not just for compliance, but for care.